Based upon profound knowledge in aeronautical engineering and many years of experience as burr manufacturer, our etzMAX-series defines a new grinding solution.

Our vision has always been to simplify grinding while at the same time ensuring maximum quality. Pulling great shots without wasting neither time nor beans shouldn`t be about science & research but should be plain and simple.

Also, we wanted the system to be easily accessible, thus giving users the opportunity to replace components themselves.

7 years of research & development reduced to the etzMAX!

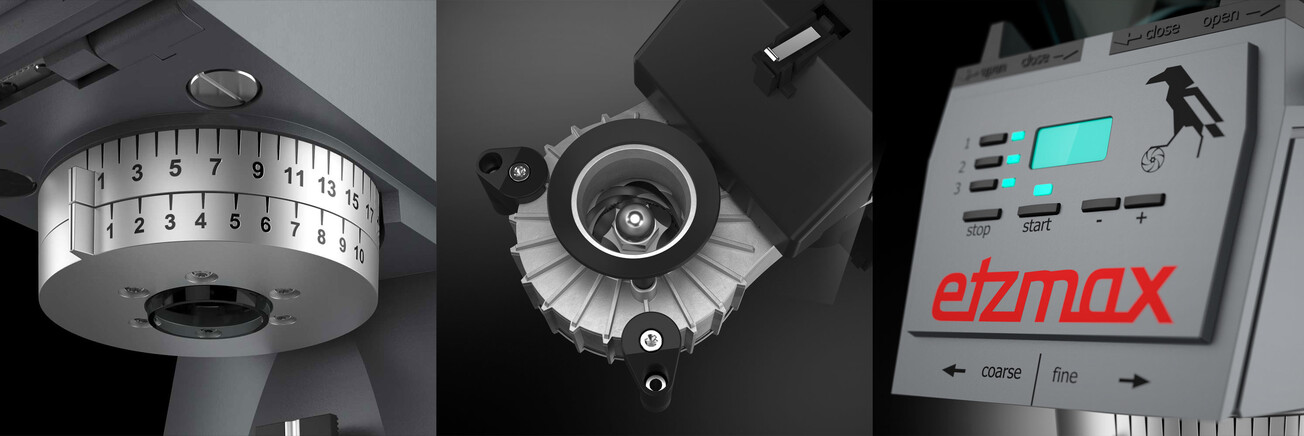

Etzingers` RRB grinding mechanism (etzJET)

Based on the rotating ring / fixed cone burr - system (RRB with Anit-Static Jig) connected directly to the macro (0.1mm) and micro (0.01mm) adjustment, our etzJET ensures maximum performance in many respects.

With low static and minimum retention (around 1g), it allows for the ground coffee to axially exit the grinder thus achieving amazing results.

Burrs and Burr Geometry have been adapted to motor power and rotating rate so to allow for maximum efficiency (higher speed = lower power consumption), less fines, better particle distribution, constant feed regardless of hopper fill level, minimal warming of ground coffee, accurate settings with maximum repeatability and an identical point of reference for all grinders.

Replaceable etzJET-versions (LT/LM/P)

etzJET-LT: body made of fiberglass-reinforced plastic and ring burr made of machining steel (life-span: around 700kg)

etzJET-LM: body made of zinc die-cast and ring burr made of high-quality tool steel (life-span: up to 1000kg based on use/settings/roast)

etzJET-P: as LM but includes an Extended-Rush-Hour-Feature (Circulation Cooling) to maintain a minimum heat level even when under higher demand

Our newest version etzMAX X (based on the same RRB mechanism) uses a new AC-motor with an unlimited service time.

"Simplicity is the soul of efficiency."

Austin Freeman